Roofing has evolved far beyond mere protection from the elements. Today, homes and commercial spaces increasingly rely on colour-coated roofing sheets to combine durability with aesthetic appeal. These metal roofing sheets not only shield buildings from harsh weather but also add a vibrant, modern touch to any structure (Learn more about the benefits of coloured roofing sheets). But have you ever wondered how these sheets journey from raw materials to the striking roofs that enhance our buildings?

Let’s Explore the Process of a Colour-coated Roofing Sheet

Manufacturing of a Colour Coated Sheet

The journey begins in a factory, where high-quality galvalume sheets serve as the foundation. Colour-coated galvalume roofing sheet manufacturers carefully select these raw materials for strength, corrosion resistance, and longevity. The sheets are cleaned, treated, and prepared for coating. This process ensures that the final product not only withstands heavy rain, heat, and UV exposure but also maintains its appearance for years.

Once prepped, the sheets move to the coating line. Advanced machines apply a primer layer, followed by a rich, durable colour layer. This is where the magic happens—transforming ordinary galvalume metal into coloured roofing sheets in an array of shades. Some factories, like ours, even offer customizable colours, allowing architects and homeowners to match their roofing to the overall building design.

Quality Control to Ensure Durability and Consistency

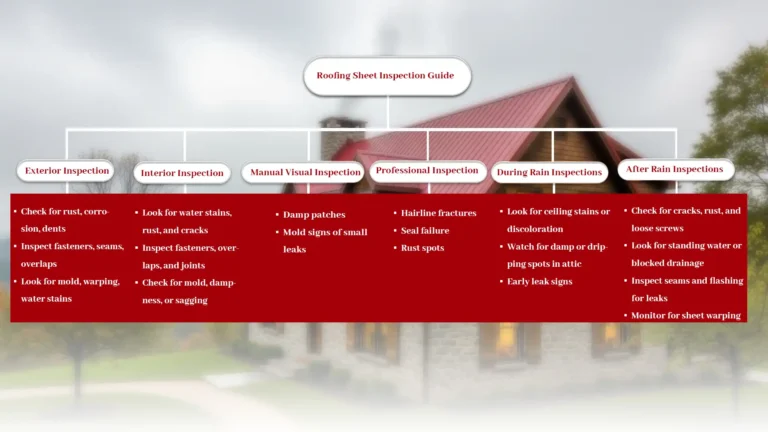

Before leaving the factory, each colouring roofing sheet undergoes rigorous quality checks. Engineers test for thickness, adhesion, corrosion resistance, and colour consistency. This stage is crucial because some roofing sheets are exposed to extreme weather conditions if they are not matched correctly in terms of quality. A sheet that passes these tests is ready to endure years of sun, rain, and wind without fading, rusting, or peeling.

High-quality colour-coated GL sheets are often backed by warranties, reflecting manufacturers’ confidence in their durability. These checks ensure that every sheet meets both national standards and customer expectations.

Packaging and Transportation from Factory to Site

After quality approval, the sheets are carefully packaged. Protective films, wrapping, and bundling prevent scratches and dents during transit. Efficient logistics play a key role here, as colour-coated metal roofing sheets need to reach destination sites intact. The packaging process also includes labelling, making it easier for site managers to identify sizes, profiles, and colours. This ensures that every batch of colour-coated galvalume roofing sheets reaches the right channel partner without confusion.

Storage at Site to Maintain Sheet Condition

Upon arrival, the sheets are stored in a dry, elevated area to prevent moisture damage. Even temporary exposure to water can affect the longevity of coloured roofing sheets, so careful handling is crucial. Contractors often follow manufacturer guidelines to stack sheets properly and protect them from accidental scratches.

Installation, Bringing Roofs to Life

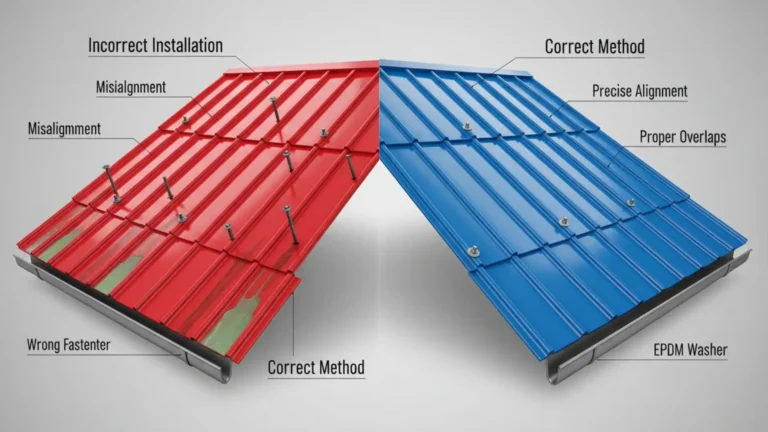

Finally, the sheets are ready for installation. Skilled workers align, fix, and secure the colour roofing sheets on the roof frame. The sheet’s lightweight nature simplifies handling, reducing installation time and labour costs. Modern roofing designs allow for overlapping sheets, ensuring waterproofing and wind resistance.

During installation, attention to detail is important. Even minor errors can affect durability, aesthetics, and performance. Once installed, these roofs provide immediate visual appeal and long-term protection, making them a top choice for residential and commercial projects alike. Learn more about the common mistakes to avoid when installing coloured roofing sheets.

The Final Result: Durable, Stylish, and Sustainable Roofs

From steel coil to finished roof, the colour-coated roofing sheets combine precision manufacturing, quality control, careful transport, protection, and expert installation. Today’s coloured roofing sheets offer energy efficiency, strength, and a splash of style, making them a sustainable choice for modern construction.

FREQUENTLY ASK QUESTIONS

Color-coated roofing sheets are usually made from galvanized steel, aluzinc (a mix of aluminum and zinc), stainless steel, galvalume, or aluminum. These materials are durable, corrosion-resistant, and lightweight, with each offering different benefits based on climate and budget needs.

Colored roofing sheets are made by cleaning and treating metal sheets like steel or aluminum. They are coated with a protective layer of zinc or aluminum, then painted with a primer and colored finish. After curing in a furnace, the sheets are cut into panels and are ready for installation.

To install color roofing sheets, first ensure the roof frame is ready. Measure and cut the sheets to fit. Lay them down with proper overlaps, securing each sheet with screws or nails. Seal edges to prevent leaks and check for ventilation to keep the roof cool and well-protected.

To buy high-quality colour roofing sheets, look for reputable brands, check the coating type (PVDF coatings are top-tier), and make sure the sheets are thick for better durability. Also, a good warranty is a sign of quality, as it shows the manufacturer trusts the longevity of their product.

Yes, when transporting color-coated roofing sheets, ensure they are loaded carefully to avoid scratches or dents. Use protective covers or padding to shield the coating. Sheets should be stacked flat and secured to prevent movement. Transporting them upright or loosely can damage the finish.