Coloured metal roofing sheets are increasingly popular in modern construction, offering both aesthetic appeal and long-lasting protection for homes and commercial buildings. With the right finish, a roof becomes a statement of style and durability. But even the most advanced colour-coated sheet is not entirely immune to the ravages of time, weather and environment.

Over the years, rust and corrosion can undermine its performance, mar its appearance and shorten its lifespan. There are many reasons for rust on coloured metal roofing sheets. Using premium coloured roofing sheets and applying the correct preventive measures, you can preserve both the beauty and function of your roof for decades.

This article will walk you through how to prevent colour coated roofing sheets from rust and corrosion with practical steps and maintenance routines.

Proven Ways to Prevent Rust and Corrosion on Coloured Roofing Sheets

Preventing corrosion begins with conscious material selection, professional installation, and disciplined maintenance. Below are the most effective anti-rust treatments for metal roofs.

-

Choose High-Quality Roofing Sheets

Investing in pre-painted, galvanised, or aluminium-zinc-coated roofing sheets provides superior protection against rust. Premium products often come with anti-corrosive colour coatings such as colour-bond finishes that resist moisture and oxidation. These coatings act as a continuous shield, preserving both strength and appearance over time.

“Al-Zn coated roofing sheets use a mix of aluminum and zinc to fight rust. This combination offers stronger, longer-lasting protection, especially in coastal, humid, or industrial areas where regular zinc coatings can wear out faster.”

-

Ensure Proper Installation

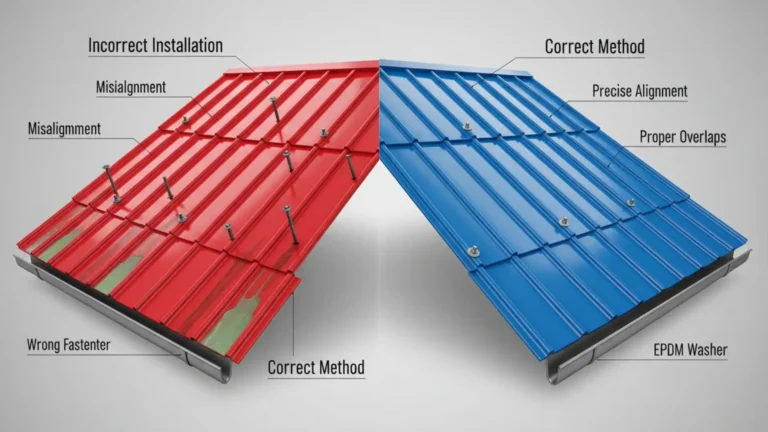

Engage experienced roofing professionals who follow correct installation protocols. Proper handling prevents scratches, while the use of rust-resistant screws, sealing washers, and compatible fasteners avoids galvanic reactions. The correct slope and drainage planning ensure that rainwater flows off efficiently without pooling or seeping into joints. Learn about the common mistakes to avoid when installing coloured roofing sheets.

-

Apply Protective Coatings or Paints

Periodic re-coating adds an extra layer of protection. Use specialised anti-corrosion paints, ideally with UV-resistant and waterproof properties. Advanced coatings like epoxy-based or polymer-bonded sealants offer longer durability and even self-healing properties that resist minor abrasions.

-

Regular Cleaning and Inspection

A consistent cleaning schedule, at least twice annually that helps prevent rust formation. Use mild detergents and soft brushes to remove dirt, bird droppings, and residue. During inspections, pay attention to scratches, loose fasteners, and small rust patches, addressing them promptly to prevent spreading.

Learn more in details

-

Maintain Proper Ventilation and Drainage

Condensation under the roof can lead to hidden corrosion. Proper roof ventilation, along with functional ridge vents and downspouts, ensures moisture control. An effective drainage system prevents water accumulation, thereby protecting the structural layers beneath.

Conclusion

The longevity and appeal of coloured roofing sheets depend on the quality of materials, precision in installation, and consistent care. By addressing minor issues early and following preventive measures, you can safeguard your roof from rust and corrosion while preserving its colour and strength for decades. A rust-free roof not only enhances structural integrity but also elevates the value and appearance of your property.

FREQUENTLY ASK QUESTIONS

It’s advisable to inspect your roof at least twice a year — before and after monsoon or winter seasons — to detect any signs of corrosion or coating damage early.

Aluminium-zinc (Galvalume) or colour-bond coatings provide superior resistance to rust and corrosion, especially in humid or coastal environments.

Yes, but only after proper surface preparation. Remove rust completely, apply a primer, and use high-quality anti-corrosive paint for long-lasting results.

Yes, provided they have marine-grade or zinc-aluminium coatings designed to resist salt-laden air and high humidity conditions common in coastal regions.