Selecting the right roofing material is one of the most important decisions in any construction project. The roof defines not only the strength and resilience of a building but also its capacity to withstand changing climates. Among modern solutions, the colour coated sheet stands out for its exceptional durability and thermal efficiency, also visual appeal.

Across both residential and industrial sectors, there is a growing preference for roofing systems that combine longevity with design flexibility. Homeowners, builders, and architects are increasingly choosing coloured roofing sheets for their corrosion resistance, thermal insulation properties and clean aesthetic lines.

This article explores the common roofing sheet installation mistakes to help you achieve a long-lasting, weather-resistant and visually consistent roof.

Why Proper Installation Matters for Coloured Roofing Sheets

Before you identify what can go wrong, it is important to recognise why correct installation is important. A roof is not a single component; it is an integrated system where every element, from sheet alignment to fastener placement, affects its overall performance.

Improper installation can lead to leaks, corrosion and structural weakness, often long before the product’s rated lifespan. In contrast, well-installed coloured roofing sheets enhance energy efficiency, ensure proper insulation and deliver lasting structural stability. Proper slope design, joint sealing and sheet alignment also ensure better temperature control and acoustic comfort indoors. Therefore, whether it’s a residential project or a commercial shed, accurate installation is the foundation of every durable roof.

What Are the Most Common Mistakes When Installing Coloured Roofing Sheets?

Even the most premium material can fail if the fundamentals of installation are ignored. The following are the most frequent roofing sheet installation mistakes, along with essential measures to prevent them.

-

Ignoring Manufacturer Guidelines

Every roofing sheet manufacturer provides installation recommendations that safeguard both performance and warranty. These include the correct slope, spacing between fasteners, overlap width, and sealing method. Ignoring these details can compromise the weather-tightness and warranty of your colour coated roofing sheets. Always refer to the technical datasheet and follow the guidelines carefully. Investing time in understanding these specifications ensures that your colour coated roofing sheets perform at their optimal capacity for years.

-

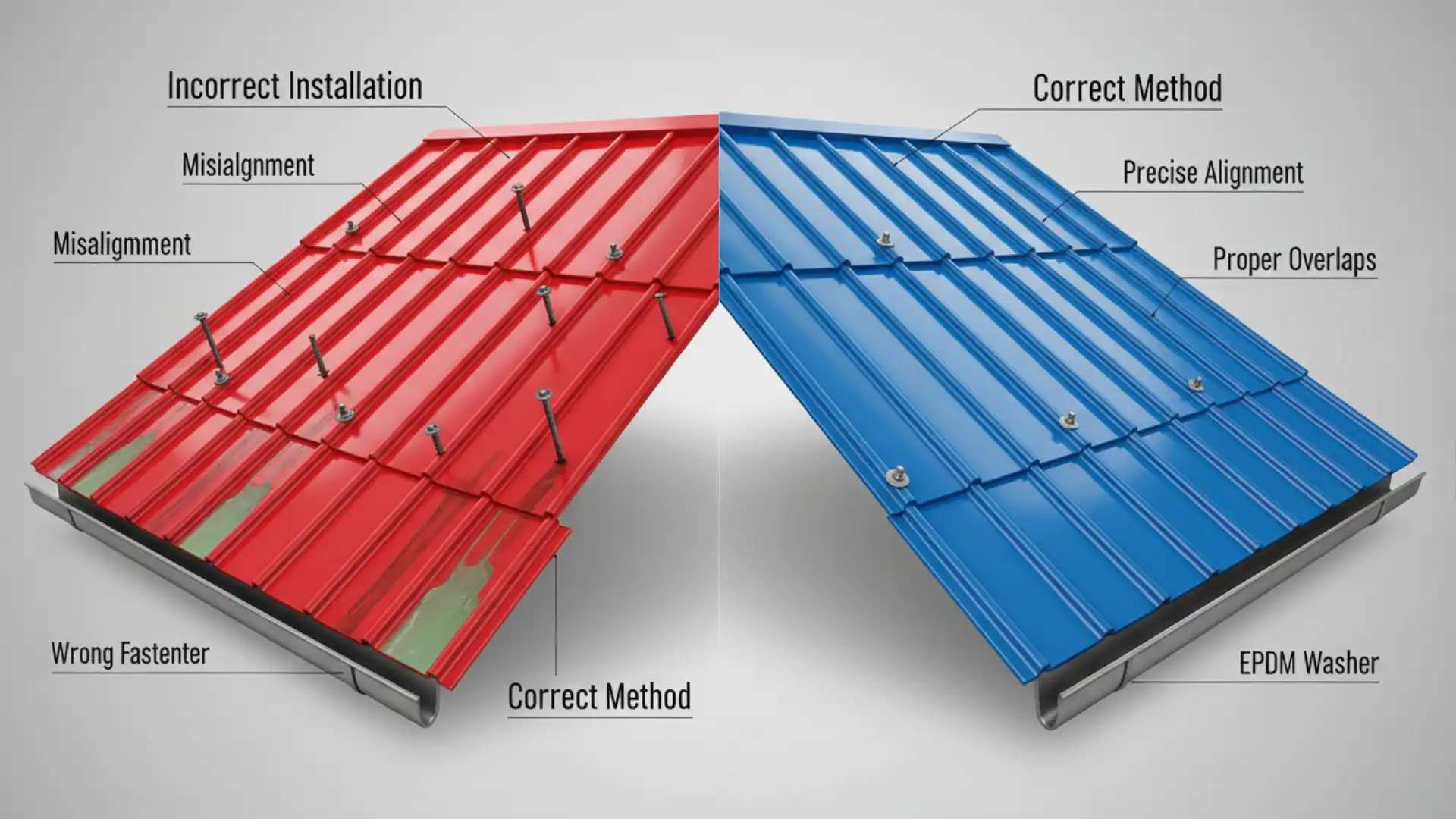

Using Incorrect Fasteners or Over-Tightening Screws

Fasteners may appear minor, yet they play a decisive role in the roof’s longevity. Using incompatible screws can cause galvanic corrosion, while over-tightening damages both the coating and the washer seal. Conversely, under-tightening allows water ingress during rainfall. Professionals recommend self-drilling screws made of compatible materials with EPDM washers for lasting protection. Each screw must be driven at a right angle using a torque-controlled driver. This attention to detail prevents water leaks and preserves coating integrity over the long term.

-

Overlooking Thermal Expansion and Contraction

Metal roofs naturally expand in heat and contract in cooler conditions. If installers fail to accommodate this movement, sheets may warp, produce noise or develop stress fractures. To address this, appropriate spacing and flexible fixings must be included during installation. Expansion joints should be provided in long roof spans to relieve pressure and maintain alignment. Understanding how to properly install metal roofing sheets with thermal allowances not only ensures stability but also prevents deformation during seasonal temperature fluctuations.

-

Poor Handling and Storage Before Installation

The longevity of your roof begins before the first screw is fixed. Colour coated roofing sheets are manufactured with protective coatings designed to resist corrosion, but careless handling can compromise them. Sheets should always be lifted individually, not dragged and stored on flat wooden pallets under a dry and covered location. Lifting them individually instead of dragging prevents surface abrasion. These precautions preserve the integrity of the coating and ensure a uniform finish once installed.

-

Neglecting Proper Alignment and Overlap Direction

Alignment errors and incorrect overlapping are among the most frequent roof sheet overlapping mistakes. When you start the installation, even the first sheet slightly misaligned can cause an entire row to shift off-square. Similarly, incorrect overlap placement exposes seams to wind and rain. The first sheet should always be laid precisely perpendicular to the eaves line and side laps should face away from the prevailing wind. Avoiding these roofing sheet overlapping mistakes ensures both aesthetic uniformity and watertight performance.

-

Inadequate Roof Slope or Drainage Design

Slope design is fundamental to water management. An improper roof slope installation results in standing water, corrosion and possible seepage through joints. The minimum recommended slope for corrugated metal roofs is 5°, while standing seam designs can function effectively at around 3°. Drainage systems such as gutters and downpipes must be incorporated during the design stage to handle heavy monsoon rainfall. A carefully planned slope not only prevents pooling but also enhances the self-cleaning ability of the sheets, maintaining their finish and reflective quality for longer periods.

-

Skipping Regular Inspection and Maintenance After Installation

Installation marks the beginning of a roof’s lifecycle, not the end of it. Over time, screws can loosen, sealants may deteriorate, or environmental debris may accumulate, particularly near joints and valleys. Ignoring periodic inspection accelerates deterioration. It is advisable to inspect the roof every six months, ideally before and after the monsoon season. Check for loose fasteners, worn washers, and any exposed metal edges. Cleaning dust and leaves also prevents surface discolouration. Consistent maintenance helps ensure that coloured roofing sheets retain their performance and visual appeal for decades.

Conclusion

The installation of a colour coated sheet is a precise process that combines engineering knowledge with practical skill. Every phase from aligning sheets to tightening the final screw contributes to the overall strength and appearance of the roof.

Avoiding common errors such as neglecting guidelines, over-tightening screws or ignoring thermal movement can prevent costly repairs later. When installed correctly, coloured roofing sheets deliver unmatched resilience, energy efficiency and design versatility suitable for India’s varied climate zones.

A well-installed roof does more than protect, it enhances the value, efficiency and lifespan of the entire structure.

FREQUENTLY ASK QUESTIONS

A minimum slope of 5° is recommended for corrugated profiles, while concealed-fix or standing seam systems can function effectively at 3°, depending on the design and manufacturer’s instructions.

A side lap of one corrugation and an end lap of around 200–250 mm are generally adequate, though exact measurements should always follow the sheet profile and slope recommendations.

It is best to avoid installation during heavy rain or when sheets are damp. Moisture during fixing can trap condensation and lead to early corrosion or coating delamination.

A biannual inspection before and after the monsoon is ideal. Cleaning debris, checking for loose screws, and retouching minor coating damage helps maintain both strength and appearance.