Introduction

If you’re building a roof, wall cladding, or any structure that needs to survive harsh weather, the choice of metal sheets can make all the difference.

For years, galvanised iron (GI) sheets have been the go-to. But there’s a new contender that’s turning heads, Al-Zn alloy coated sheets (also known as Aluzinc sheets). And they are proving to be stronger, longer-lasting and more cost-effective in the long run.

What Makes Al-Zn Coating Different from Regular GI Sheets?

“GI sheets use a zinc coating to prevent rust. This works well, but zinc alone has limitations, especially in tropical, coastal or industrial areas where corrosion can be aggressive.

Al-Zn alloy coated sheets, on the other hand, use a blend of aluminium (55%), zinc (43.5%), and silicon (1.5%). This combination offers a dual shield; aluminium gives long-term corrosion resistance, while zinc provides sacrificial protection. The result? Your sheets not only last longer but also keep their structural integrity and shine for years.”

Difference of Al-Zn Coated Sheets and Regular GI Sheets on Specification

| Feature | Al-Zn Alloy Coated Sheets (Aluzinc) | Regular GI Sheets |

|---|---|---|

| Coating Composition | 55% aluminium, 43.5% zinc, 1.5% silicon | 100% zinc |

| Corrosion Resistance | 2-4 times better than GI sheets | Good, but prone to faster rusting in harsh climates |

| Heat Resistance | Up to 315°C without surface damage | Limited high-heat tolerance |

| Surface Appearance | Smooth, spangled finish | Dull or standard galvanised look |

| Lifespan | 30-40 years (with proper maintenance) | 15-20 years |

| Maintenance Needs | Low | Higher over time |

| Cost Efficiency | Higher upfront cost but lower lifecycle cost | Lower upfront cost but higher replacement cost |

Learn more about the specification of aluzinc sheet.

What are the Advantages of Al-Zn Coating Sheets Over Regular GI Sheets?

-

Longer Life, Less Hassle; Many people ask:

How long do Al-Zn coated sheets last compared to GI sheets? The answer is simple: nearly double or more, depending on environmental conditions. This means fewer replacements, less downtime and better long-term savings.

-

Better Resistance to Extreme Weather:

Whether it’s heavy rain, scorching sun or hail storm, AluZinc alloy coated sheets handle it all without losing strength or beauty.

“The 5% Al–Zn coatings exhibit much better corrosion resistance than the conventional hot-dip galvanizing steels under salt spray tests.” – From a assessment of hot-dip 5% Al–Zn coatings in chloride environments, written by H.C Shih, J.W Hsu, C.N Sun, S.C Chung on ScienceDirect.” Source

-

Lightweight Yet Strong:

Thanks to optimised Aluzinc sheet density, these sheets deliver an excellent strength-to-weight ratio, making installation easier and reducing load on your structure.

-

Aesthetic Appeal:

The silvery, spangled finish or colour coated sleek finish reflects a modern and premium appeal, ideal for projects where visual appeal matters just as much as durability.

If you’re evaluating GI sheets, pay close attention to the GI sheet’s thickness and dimensions. While thicker GI sheets may last longer than thinner ones, they still won’t match the corrosion resistance of Al-Zn alloy-coated options.

Why Paying a Little More Now Can Save You a Fortune Later

At first glance, aluminum zinc alloy coated sheets may seem like a pricier option compared to regular GI sheets. However, the real value becomes clear when you look beyond the initial investment. When sourced from a reliable Al-Zn alloy coated sheet manufacturer, these sheets offer a significantly longer lifespan, require minimal maintenance, and are far less likely to need costly replacements. Over the decades, the savings on repairs and replacements can be substantial.

It’s much like choosing a premium product that delivers consistent performance for years, rather than settling for a cheaper option that needs frequent repairs or replacements. This becomes even more significant in large-scale projects, where each replacement cycle adds up to major expenses and disruption.

By investing slightly more at the outset, you secure a roofing solution that offers peace of mind, durability and genuine long-term value. In construction, as in life, quality always pays for itself many times over.

Real World Experiences

Written by a user on Metal Roofing Alliance – Source

Final Word

“Zn/Al alloy coated sheets are the smarter choice over regular GI sheets. They combine strength, resistance, durability, long-lasting and superior protection – everything that modern construction demands.”

FREQUENTLY ASK QUESTIONS

Yes, they can be easily painted or coated for additional aesthetic appeal without affecting their protective properties.

No, standard metal sheet installation tools and techniques work just fine.

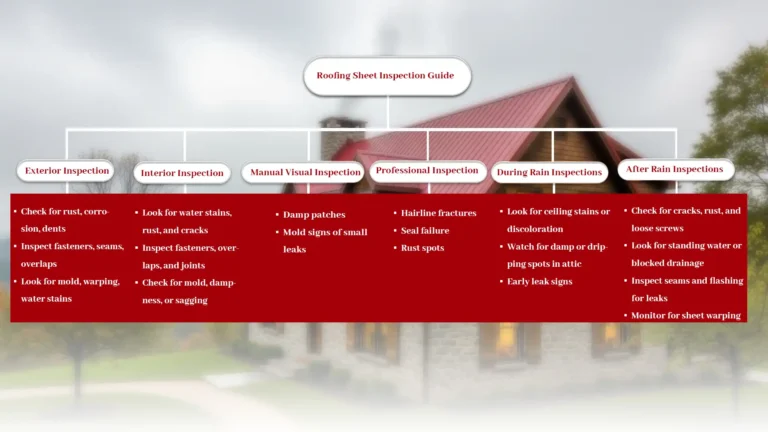

Routine cleaning and occasional inspection are usually enough. They don’t require frequent maintenance like GI sheets.

Yes, they can directly replace GI sheets without major structural changes.